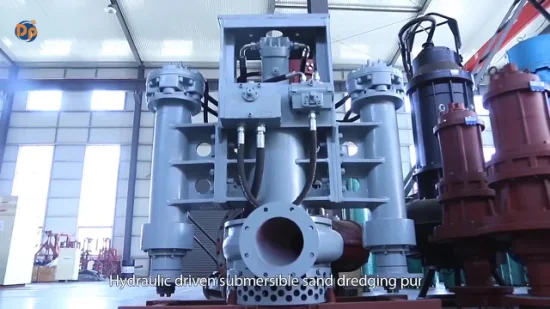

High Pressure Industrial Submersible Slurry Pump with Agitator Seawater Pump

submersible slurry pump mud pump with agitator mud pump General InformationThe Depon SS Series Submersible Slurry Pumps

Basic Info.

| Model NO. | SS100-25-22 |

| Influent Type of Impeller | Single Suction Pump |

| Position of Pump Shaft | Vertical Pump |

| Pump Casing Combined | Verticaljoint Surface Pump |

| Mounting Height | Suction Centrifugal |

| Impeller | Open, Simi-Open, Closed |

| Usage | Pump, Pumps, Condensate Pump, Ash Pumps, Circulating Pump, Slurry Pump, Sand Pump |

| Color | as Customer Required |

| Frequeccy | 50Hz/60Hz |

| Application 1 | Mining |

| Application 2 | River Dredging |

| Certificate | CE SGS |

| Drive | Electric Motor |

| Voltage | 220V/380V/410V/460V/High Voltage |

| Bearing | Imported Brand |

| Material | A05, A07, A49, CD4MCU |

| Transport Package | Plywood Cases/ as Customer Required |

| Specification | DN80-DN400mm |

| Trademark | Depon |

| Origin | China |

| HS Code | 8413810090 |

| Production Capacity | 7000sets/Year |

Product Description

submersible slurry pump mud pump with agitator mud pumpGeneral InformationThe Depon SS Series Submersible Slurry Pumps are electro submersiblcentrifugal pumps designed for pumping abrasive and high density slurries in mining, heavy industry, civil construction and municipal applications.ApplicationsTransfer of waste water, effluent and solids laden water for:• Building Services• Sumps and Basements• Mining• Civil Construction• Industry• Municipal• Processing• Water TreatmentTechnical Data

| Flowrate | 6.5 - 670l/s |

| Max. Head | 64m |

| Max. Working Pressure | 640kPa |

| Max. Solid Size | 10 - 60mm |

| Discharge | 80 - 400mm |

| Motor Sizes | 7.5 - 315kW |

| Operating Speed | 980-1480RPM |

Features• 27% chrome white iron impeller.• 27% chrome white iron integral agitator.• 27% chrome white iron volute.• Replaceable 27% white iron back plate.• 420 stainless steel shaft• 420 stainless steel shaft sleeve.• 420 stainless steel stainer.• All fasteners 420 stainless steel.• Large cut water casing clearance.• Low speed electro-submersible motor provides reliable continuous operation.• Motor incorporates thrust bearing temperature and moisture sensors.• F class motor insulation as standard, with optional H class insulation available for reliable operation in high temperature applications.• Heavy duty cast iron motor construction.• Heavy duty mild steel support frame with round base provides excellent stability.• Double mechanical seal with carbon/ceramic on wet end and tungsten/ceramic on the drive end provide effective sealing between motor and wet end.• Mechanical seals are oil bath lubricated.• External cooling options available.• Available with a wide range of protective oatings and paint options.• Oil chamber incorporates a water leakage probe which detects when water-to-oil ratio is too high and cuts off power to prevent motor damage due to oil contamination.• Motor incorporates a float switch in the bottom to detect the ingress of water and cut power to prevent motor damage. Motor stator incorporates shutdown temperature control sensors which automatically detect excessive motor temperatures and shut motor down to prevent damage.• World wide backup and service.Materials

| NO. | Description | Standard Material | Material Options |

| 1 | Support Frame | Mild Steel | |

| 2 | Strainer | 420 Stainless Steel | |

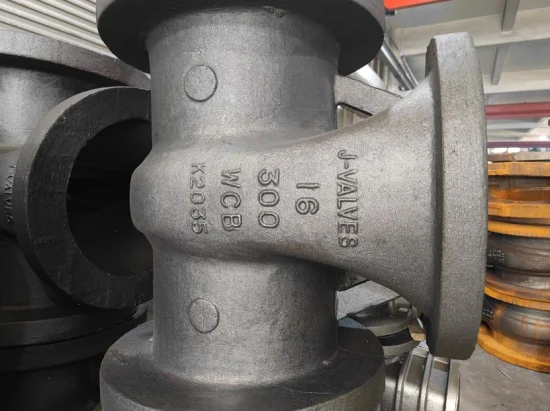

| 3 | Pump Casing | Cr27 White Iron | SS316, A49,CD4MCu |

| 4 | Back Plate | Cr27 White Iron | SS316, A49,CD4MCu |

| 5 | Impeller | Cr27 White Iron | SS316, A49,CD4MCu |

| 6 | Agitator | Cr27 White Iron | SS316, A49,CD4MCu |

| 7 | Oil Chamber Housing | Cast Iron | |

| 8 | Shaft | 420 Stainless Steel | |

| 9 | Shaft Sleeve | 420 Stainless Steel | |

| 10 | Wet End Mechanical Seal | 304 Stainless Steel | |

| 11 | Motor Mechanical Seal | 304 Stainless Steel | |

| 12 | Motor Casing | Cast Iron | |

| 13 | Motor Cooling Jacket | Fabricated Mild Steel | |

| 14 | Lifting Brace | Mild Steel | |

| 15 | Bearing Covers | Cast Iron | |

| 16 | Oil Chamber Cover | Cast Iron |

Model Selection Table

| Model | Outlet Dia. (mm) | Capacity (m³/h) | Head (m) | Power (Kw) | Speed (r/min) | Max.Dia.of Solid (mm) | Pump Weight (kg) |

SS45-15-5.5 | 80 | 45 | 15 | 5.5 | 1460 | 13 | 100 |

| SS15-20-5.5 | 80 | 15 | 20 | 5.5 | 1460 | 13 | 100 |

| SS30-30-7.5 | 80 | 30 | 30 | 7.5 | 1460 | 13 | 114 |

| SS50-26-11 | 80 | 50 | 26 | 11 | 1460 | 13 | 165 |

| SS75-25-15 | 100 | 75 | 25 | 15 | 1460 | 13 | 220 |

| SS150-18-18.5 | 150 | 150 | 18 | 18.5 | 980 | 32 | 550 |

| SS200-12-22 | 150 | 200 | 15 | 22 | 980 | 45 | 580 |

| SS60-46-30 | 150 | 60 | 46 | 30 | 980 | 21 | 700 |

| SS150-30-30 | 150 | 150 | 30 | 30 | 980 | 21 | 550 |

| SS300-20-37 | 200 | 300 | 20 | 37 | 980 | 28 | 775 |

| SS200-30-45 | 150 | 200 | 30 | 45 | 980 | 36 | 1000 |

| SS500-15-45 | 250 | 500 | 15 | 45 | 980 | 46 | 1100 |

| SS250-35-55 | 150 | 250 | 35 | 55 | 980 | 36 | 1140 |

| SS600-15-55 | 250 | 600 | 15 | 55 | 980 | 46 | 1140 |

| SS350-35-75 | 200 | 350 | 35 | 75 | 980 | 28 | 1550 |

| SS500-20-75 | 200 | 500 | 20 | 75 | 980 | 25 | 1550 |

| SS200-60-90 | 150 | 200 | 60 | 90 | 980 | 14 | 1550 |

| SS400-40-90 | 200 | 400 | 40 | 90 | 980 | 28 | 1550 |

| SS600-30-110 | 200 | 600 | 30 | 110 | 980 | 28 | 1970 |

| SS1000-18-110 | 300 | 1000 | 18 | 110 | 980 | 50 | 1970 |

| SS500-45-132 | 200 | 500 | 45 | 132 | 980 | 28 | 2000 |

| SS1000-22-132 | 300 | 1000 | 22 | 132 | 980 | 50 | 2000 |

| SS650-52-160 | 200 | 650 | 52 | 160 | 980 | 28 | 2650 |

| SS780-50-185 | 300 | 780 | 50 | 185 | 980 | 38 | 3330 |

| SS800-55-220 | 300 | 800 | 55 | 220 | 980 | 38 | 3400 |

| SS1250-35-220 | 350 | 1250 | 35 | 220 | 980 | 45 | 3400 |

| SS1750-30-250 | 350 | 1750 | 30 | 250 | 980 | 55 | 3500 |

| SS2000-35-315 | 400 | 2000 | 35 | 315 | 980 | 60 | 3700 |

previous:

Super T Self

Garden Pump (AUTO :next

Send to us