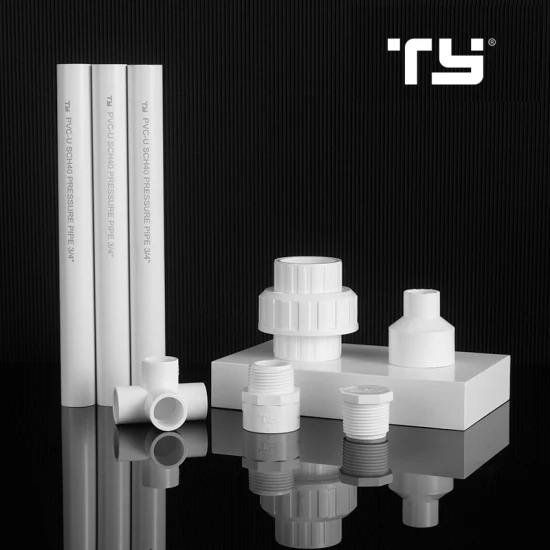

Spring Loaded Steam Safety Valve / Pressure Relief Valve

Function of piston type pressure reducing valve the piston type pressure reducing valve mainly controls the fixed outlet

Basic Info.

| Model NO. | DIN 901/ 902 |

| Structure | Spring |

| Material | Brass |

| Packing | Pallets |

| Transport Package | Export Case |

| Specification | 3/4", 1", 1-1/4, 1-1/2", 2" |

| HS Code | 8481804090 |

Product Description

Function of piston type pressure reducing valvethe piston type pressure reducing valve mainly controls the fixed outlet pressure of the main valve. the outlet pressure of the main valve doesnot change due to the change of the inlet pressure or the change of the inlet flow of the main valve.Commonly used in industrial water supply,fire water supply and domestic water pipe network system.

| NPS | D | L | H | W |

| 1/2" | 10 | 60 | 95 | 40 |

| 3/4" | 10 | 60 | 95 | 40 |

| 1" | 14 | 70 | 102 | 50 |

| 11/4" | 20 | 80 | 124 | 60 |

| 11/2" | 24 | 85 | 144 | 60 |

| 2" | 32 | 100 | 144 | 70 |

| 21/2" | 38 | 125 | 168 | 90 |

| 3" | 50 | 150 | 192 | 90 |

| 4" | 65 | 195 | 220 | 130 |

Qingdao Haiying valves could manufacture/supply Resilient seated and Multi Hard-seal buttefly valve and ball valves used for Lubricating oil,fresh oil,fresh water,sea water ,compressed air pipe line and etc. There are CNC lathes ,CNC milling machines,CNC boring machines machining ,valve automatic testing bench ,spray painting line and other advanced equipment in our outsourced factory.so it could ensure delivery on time and high quality.we sincerely welcome all friends to visit our company for seeking cooperation in creating a win-win future

FAQ

- Could you produce customized product?

2. How to ensure the valve quality??

a.Firstly,we inspect the casting when get it one by one and will abandon it if defect castings.such as blowholes&pinholes is defects castings.

b.We will inspect and check about valve dimension after machining.Allowable error to standard is 1.5mm for longth(above DN50 valves)

c.All items must be inspected by hydraulic test after assemble.and more important ensure that valves are inspected by operator in according with hydraulic test criteria including pressure&time.

d.Coat oil for anti-rust inside of the valve body and paint checking.

3.How if your valve warranty period?

Usually,the warranty period for valves is 14 monthes,however,we will solve or replace new valves once find fault items to our old stock customers no matter how long.

Send to us